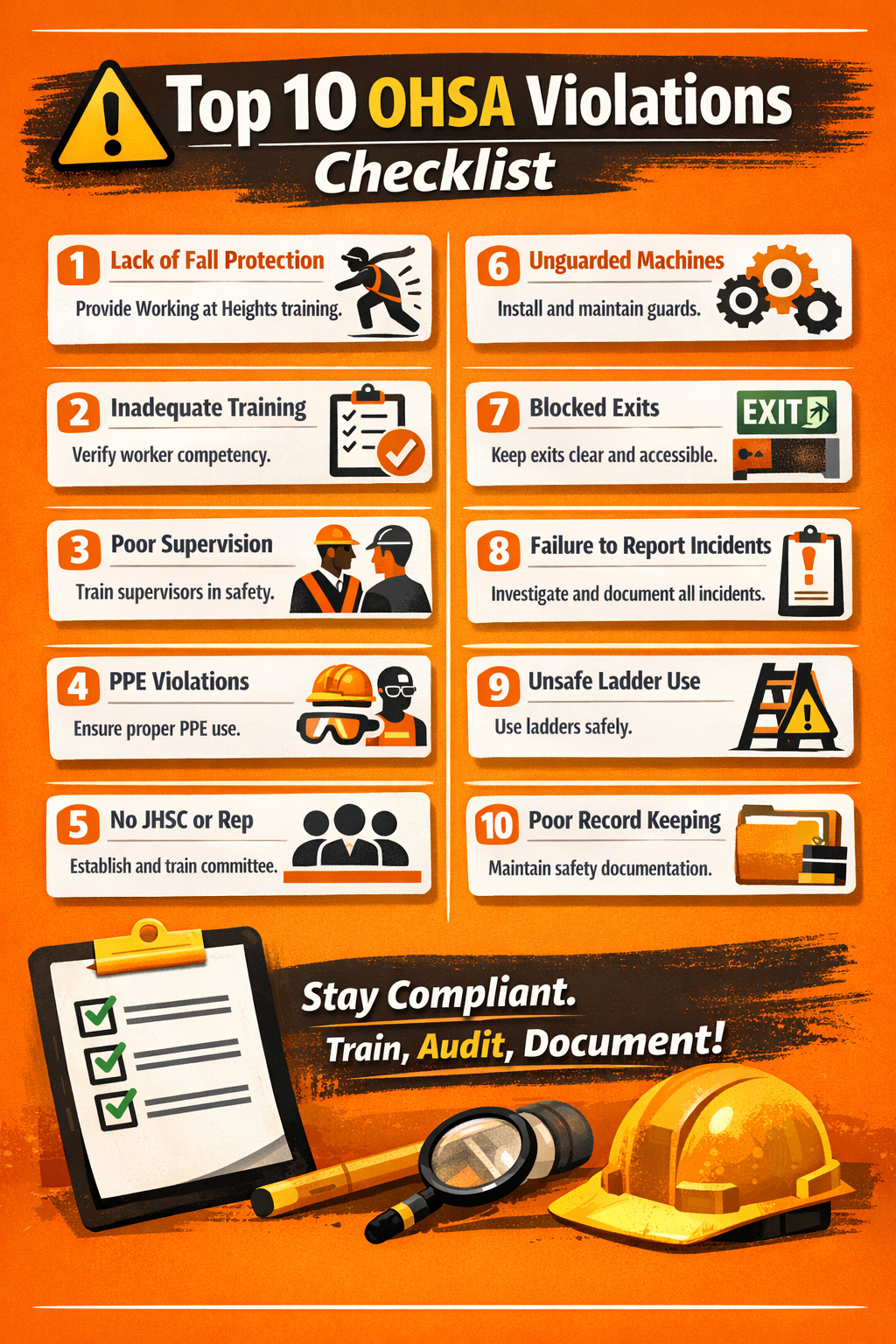

Every year, Ontario workplaces receive thousands of Ministry of Labour orders under the Occupational Health and Safety Act. Most of these orders are not complex or unexpected. They come from the same repeat issues across construction, industrial, warehousing, and commercial environments. Missing fall protection. Poor supervision. Incomplete training records. Unsafe equipment. Inadequate worker protection.

These violations are costly. They disrupt operations, increase injury risk, and expose employers and supervisors to legal consequences. More importantly, they are preventable.

This article breaks down the top 10 OHSA violations most commonly cited in Ontario workplaces. Each violation is explained in plain language, followed by clear prevention steps and training solutions that help employers meet their legal duties. If your goal is to reduce incidents, pass inspections, and prove due diligence, understanding these violations is the first step.

- Violation #1: Lack of Fall Protection and Working at Heights Compliance

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #2: Inadequate Training and Worker Competency

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #3: Missing or Ineffective Supervision

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #4: Improper Use or Lack of Personal Protective Equipment

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #5: Failure to Establish or Maintain a Joint Health and Safety Committee

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #6: Inadequate Equipment Guarding and Machine Safety

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #7: Poor Housekeeping and Blocked Exits

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #8: Failure to Report or Investigate Incidents

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #9: Unsafe Use of Ladders and Access Equipment

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Violation #10: Poor Documentation and Record Keeping

- What the Violation Looks Like

- Why Inspectors Issue This Order

- How to Prevent This Violation

- Training and Compliance Solutions

- Final Takeaway: Most OHSA Violations Are Preventable

- How Achieve Safety Helps Prevent OHSA Violations

Violation #1: Lack of Fall Protection and Working at Heights Compliance

Fall protection violations are the most frequently issued orders in Ontario workplaces. These orders appear across construction sites, warehouses, maintenance operations, and industrial facilities. Inspectors often find workers exposed to fall hazards without proper training, equipment, or controls.

What the Violation Looks Like

This violation occurs when:

- Workers are exposed to fall hazards without guardrails or fall arrest systems

- Ladders are used improperly or unsecured

- Roof edges and openings are not protected

- Workers perform elevated tasks without approved Working at Heights training

- Harnesses or anchor points are missing, damaged, or incorrectly used

Even short duration tasks can trigger orders if fall protection is missing.

Why Inspectors Issue This Order

Falls remain the leading cause of critical injuries and fatalities in Ontario workplaces. OHSA and the Construction Projects Regulation require employers to eliminate or control fall hazards before work begins. Inspectors issue orders when fall risks are visible and unaddressed.

How to Prevent This Violation

Employers can reduce fall protection violations by:

- Identifying all tasks where a worker could fall

- Installing guardrails or engineered controls where possible

- Providing approved Working at Heights training for construction work

- Training workers on proper ladder selection and setup

- Inspecting harnesses, lanyards, and anchor points before use

- Enforcing safe work procedures consistently

Prevention starts with planning before work begins.

Training and Compliance Solutions

Achieve Safety helps prevent fall protection violations through:

- Working at Heights Training for construction environments

- Ladder Safety Training for warehouses and maintenance work

- Fall Protection Training for industrial settings

- Site audits that identify fall hazards before inspections occur

These programs help employers demonstrate due diligence and reduce repeat orders.

Violation #2: Inadequate Training and Worker Competency

Lack of training is one of the most common findings during Ministry of Labour inspections. Inspectors regularly issue orders when workers cannot demonstrate that they are trained, informed, and competent to perform their tasks safely.

What the Violation Looks Like

This violation occurs when:

- Workers operate equipment without documented training

- Forklift or lift truck operators lack competency records

- Workers use ladders, fall protection, or PPE without instruction

- Supervisors cannot confirm worker qualifications

- Training records are missing, outdated, or incomplete

Even experienced workers can trigger an order if training cannot be verified.

Why Inspectors Issue This Order

OHSA requires employers to ensure workers are trained and competent before performing work. Training is not optional and cannot be assumed based on experience alone. Inspectors often ask workers to explain hazards or demonstrate equipment use. If workers cannot do so safely, an order is issued.

How to Prevent This Violation

Employers can prevent training related orders by:

- Identifying task specific training requirements

- Providing training before work begins

- Verifying competency through practical assessment

- Keeping training records organized and accessible

- Updating training when equipment or job tasks change

- Ensuring supervisors understand training requirements

Training must match the hazards present in the workplace.

Training and Compliance Solutions

Achieve Safety helps address training gaps through:

- Forklift Training for powered equipment operators

- Working at Heights Training for construction tasks

- Ladder Safety Training for warehouse and maintenance work

- WHMIS Training for hazardous products

- Supervisor Awareness Training to strengthen oversight

Training records and competency assessments support due diligence during inspections.

Violation #3: Missing or Ineffective Supervision

Supervision failures are a frequent underlying factor in serious workplace incidents. Ministry of Labour inspectors issue orders when supervisors are absent, untrained, or unable to control unsafe work practices.

What the Violation Looks Like

This violation occurs when:

- Supervisors are not present while hazardous work is being performed

- Unsafe work practices continue without correction

- Workers are not given clear safety instructions

- Supervisors lack knowledge of OHSA duties

- New or young workers are left unsupervised

- Hazards are reported but not addressed

A supervisor does not need to be physically present at all times, but they must actively oversee work.

Why Inspectors Issue This Order

OHSA requires employers to appoint competent supervisors. A competent supervisor must understand the Act, know workplace hazards, and be able to direct work safely. Inspectors issue orders when supervisors cannot demonstrate control or awareness of hazards.

How to Prevent This Violation

Employers can reduce supervision related orders by:

- Ensuring supervisors understand their legal duties

- Providing supervisor safety training

- Clearly defining supervisory authority

- Requiring supervisors to conduct daily site checks

- Documenting safety discussions and corrective actions

- Ensuring supervisors stop unsafe work immediately

Effective supervision creates consistent safety behaviour across the workplace.

Training and Compliance Solutions

Achieve Safety supports strong supervision through:

- Supervisor Awareness Training

- Due Diligence Safety Training

- Safety audits that evaluate supervisory practices

- Incident investigation training to improve hazard control

Strong supervisors reduce repeat violations and improve compliance outcomes.

Violation #4: Improper Use or Lack of Personal Protective Equipment

Personal protective equipment violations are common across construction, manufacturing, warehousing, and maintenance environments. Inspectors frequently issue orders when PPE is missing, damaged, or not used correctly.

What the Violation Looks Like

This violation occurs when:

- Workers are not wearing required PPE

- PPE is provided but not enforced

- Equipment is damaged or improperly fitted

- PPE does not match the hazard

- Workers remove PPE during tasks

- Employers fail to assess PPE needs

Providing PPE alone does not meet OHSA requirements.

Why Inspectors Issue This Order

OHSA requires employers to identify hazards and ensure appropriate protective equipment is used. Inspectors observe tasks directly. If PPE is not worn or does not provide adequate protection, an order is issued immediately.

Employer → must provide → appropriate PPE

Supervisor → must ensure → PPE is used correctly

How to Prevent This Violation

Employers can prevent PPE violations by:

- Completing hazard assessments for each task

- Selecting PPE that matches identified risks

- Training workers on proper use and limitations

- Inspecting PPE regularly

- Enforcing PPE rules consistently

- Replacing damaged equipment immediately

PPE must be the last line of defence, not the only control.

Training and Compliance Solutions

Achieve Safety helps prevent PPE violations through:

- PPE and hazard awareness training

- WHMIS Training for chemical related PPE

- Supervisor training to enforce PPE rules

- Workplace audits to verify PPE compliance

Effective PPE programs reduce injuries and inspection orders.

Violation #5: Failure to Establish or Maintain a Joint Health and Safety Committee

Ontario law requires certain workplaces to have a Joint Health and Safety Committee or a Health and Safety Representative. Inspectors regularly issue orders when these structures are missing or inactive.

What the Violation Looks Like

This violation occurs when:

- A required JHSC is not established

- Committee members are not trained

- Meetings are not held

- Inspection duties are not completed

- Minutes and records are missing

- Worker representation is inadequate

Why Inspectors Issue This Order

OHSA requires worker participation in health and safety. Inspectors check committee status early during inspections. Missing or inactive committees result in immediate orders.

How to Prevent This Violation

Employers can prevent this by:

- Determining if a JHSC or representative is required

- Appointing worker and management members

- Providing mandatory certification training

- Scheduling regular meetings

- Completing workplace inspections

- Keeping written records

Training and Compliance Solutions

Achieve Safety supports compliance through:

- JHSC Certification Training

- Safety audits that verify committee effectiveness

- Supervisor training to support worker participation

Violation #6: Inadequate Equipment Guarding and Machine Safety

Machine guarding violations are common in manufacturing, processing, and industrial workplaces. Inspectors issue orders when moving parts are exposed.

What the Violation Looks Like

This violation occurs when:

- Guards are missing or removed

- Equipment is modified without safeguards

- Workers bypass safety devices

- Lockout procedures are not followed

- Emergency stops are inaccessible

Why Inspectors Issue This Order

Unguarded machinery causes amputations and serious injuries. OHSA requires guarding to prevent access to moving parts. Inspectors act immediately when hazards are visible.

Machine Guard → prevents → contact with moving parts

How to Prevent This Violation

Employers can reduce guarding orders by:

- Installing proper guards

- Prohibiting bypassing of safety devices

- Training workers on lockout procedures

- Inspecting equipment regularly

- Stopping unsafe modifications

Training and Compliance Solutions

Achieve Safety helps through:

- Lockout and energy control training

- Basic Supervisor awareness training

- Machine safety audits

Violation #7: Poor Housekeeping and Blocked Exits

Housekeeping issues are often overlooked but frequently cited. These violations increase slip, trip, fire, and evacuation risks.

What the Violation Looks Like

This violation occurs when:

- Aisles are blocked

- Exits are obstructed

- Debris accumulates

- Spills are not cleaned promptly

- Storage encroaches on walkways

Why Inspectors Issue This Order

OHSA requires workplaces to be kept in a safe condition. Inspectors view blocked exits and clutter as immediate hazards.

Housekeeping → supports → safe movement and emergency egress

How to Prevent This Violation

Employers can prevent housekeeping orders by:

- Assigning cleaning responsibilities

- Keeping aisles and exits clear

- Removing waste promptly

- Conducting regular inspections

- Enforcing storage rules

Training and Compliance Solutions

Achieve Safety supports compliance through:

- Workplace inspections

- Supervisor awareness training

- Safety audits

Violation #8: Failure to Report or Investigate Incidents

Failure to report or investigate incidents is a serious compliance issue. Inspectors issue orders when employers cannot demonstrate proper reporting.

What the Violation Looks Like

This violation occurs when:

- Incidents go unreported

- Investigations are incomplete

- Root causes are not identified

- Corrective actions are missing

- Records are unavailable

Why Inspectors Issue This Order

OHSA requires employers to report certain incidents and investigate hazards. Inspectors review records to confirm compliance.

Incident Investigation → prevents → recurrence

How to Prevent This Violation

Employers can prevent this by:

- Training staff on reporting requirements

- Investigating all incidents and near misses

- Documenting findings and actions

- Following up on corrective measures

Training and Compliance Solutions

Achieve Safety provides:

- Accident and Incident Investigation Training

- Due diligence training

- Audit services

Violation #9: Unsafe Use of Ladders and Access Equipment

Ladder violations appear across construction, warehousing, and maintenance work. Improper use leads to frequent injuries.

What the Violation Looks Like

This violation occurs when:

- Ladders are damaged

- Improper ladder types are used

- Ladders are not secured

- Workers overreach

- Access equipment is misused

Why Inspectors Issue This Order

Falls from ladders are common and preventable. OHSA requires ladders to be used safely and maintained.

Proper Ladder Use → reduces → fall risk

How to Prevent This Violation

Employers can reduce ladder related orders by:

- Training workers on ladder selection and setup

- Inspecting ladders before use

- Enforcing three point contact

- Using alternatives when needed

Training and Compliance Solutions

Achieve Safety helps through:

Violation #10: Poor Documentation and Record Keeping

Many employers meet safety requirements but fail to document them. Inspectors issue orders when proof is missing.

What the Violation Looks Like

This violation occurs when:

- Training records are missing

- Inspection reports are incomplete

- Policies are outdated

- Corrective actions are undocumented

Why Inspectors Issue This Order

Due diligence must be proven, not assumed. Inspectors rely on records to verify compliance.

Documentation → proves → due diligence

How to Prevent This Violation

Employers can prevent documentation orders by:

- Keeping training records organized

- Documenting inspections and corrections

- Updating policies regularly

- Storing records securely and accessibly

Training and Compliance Solutions

Achieve Safety supports documentation through:

- Due Diligence Safety Training

- Supervisor training

- Compliance audits

Final Takeaway: Most OHSA Violations Are Preventable

The majority of OHSA violations issued in Ontario workplaces come from the same core gaps. Missing fall protection. Inadequate training. Weak supervision. Poor documentation. Unsafe equipment use. These issues are rarely hidden. Inspectors see them because they are visible, repeatable, and unmanaged.

The good news is that each violation outlined in this guide has a clear prevention path. Proper training. Competent supervision. Routine inspections. Strong documentation. When these systems are in place, workplaces not only reduce orders and fines, they reduce injuries and downtime.

Compliance is not about reacting to inspections. It is about building safety into daily operations.

How Achieve Safety Helps Prevent OHSA Violations

Achieve Safety works with Ontario employers to address the exact issues inspectors cite most often. This includes:

- Working at Heights and Ladder Safety Training to prevent fall protection orders

- Rough Terrain Forklift and equipment training to improve operator competency

- Supervisor Awareness and Due Diligence Training to strengthen oversight

- PPE, WHMIS, and hazard safety trainings like Respiratory Protection , Electrical Safety Awareness ,Fire Extinguisher Hot Work to control exposure risks

- Accident and Incident Investigation Training to prevent repeat events

- Safety audits and gap assessments to identify issues before inspections

A proactive audit or training program helps employers demonstrate due diligence and stay inspection ready.

If your organization wants to reduce OHSA violations, improve safety culture, and protect workers, the first step is identifying gaps and closing them before an inspector does.